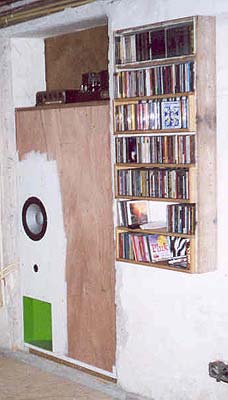

| Woefwoef7a by Peter Reinders 22/024/03 Two years ago we bought a house in Amsterdam. We had been looking for over a year to find something we liked and still was within our budget. In the end this meant we were not going to buy a house but a project. And so we did. Before we bought the house it was an office with an illegal marihuana plantation underneath! Really. We have taken out almost everything and now we are in the process of rebuilding. We (that means mostly my wife, who is a qualified carpenter and has her own one-woman carpentry business) do almost everything ourselves so it takes forever. The advantage is that you can make your home exactly the way you want it to be. The moment I saw the house I knew I wanted to include a subwoofer enclosure somewhere in the house, even though I didn't know how or where or what. I suppose this came from my youth when my granddad had years of issues of an American magazine called Audio. In it were articles about huge mansions that had enormous horns built into the basement and custom made wall-size cupboards to accommodate all the tape decks, amps and record players of the owner. It intrigued me no end. These rooms were bigger than the house we lived in! So if I had the chance to make something similar myself, albeit somewhat smaller, there was no way I could resist. In one of the walls of what is to become our living room were three doors. We decided two of them should go. This was going to be my chance! The wall was about 35cm thick and that meant that one doorway provided enough space for a 400 liter box. That should be enough. |

|

|||

|

Basic criteria:

What kind of box? Long live the www! There is so much information to be found there. For weeks I read article after article and studied site after site to find out what would be best. At first I wanted a closed box, then a vented box and after that I learned about EBS. But what I really would love to make was a transmission line. In the seventies I heard some great ones. I built a few myself but they never worked the way they should. Despite this I always kept a soft spot for them. As far as I knew it was very difficult to predict its performance and tuning them something of a black art. And then I found this website and read the articles of Martin King. After that I had to give it a try at least |

||||

|

|

Choice of driver

|

|||

|

|

||||

Listening Yes I can make the whole building shake and rattle. But properly set up the most impressive feature is how unimpressive it is. You don't notice that everything under 80hz is coming out of the wall. I haven't been able to do any measurements, but I know it goes seriously low. 20hz is clearly audible. Matching a dynamic driver to an electrostatic speaker is notoriously problematic but I've had little problems with it. If there were a downside to this project it would be the fact that tonal balance varies widely depending on your position in the room. There seems to be more bass close to the walls than more to the middle of the room. Final thoughts This project has been very rewarding. I don't expect many people will have the space or house to make this design a logical project. But I am sure that if you use the same basic ingredients and make good use of Martin King's software anybody can make a very musical sounding subwoofer. If you have any questions you are free to mail me. |

||||

|

[ <-- Back to TL Page | Projects | Woefwoef7a | Simulation Results | Drawings | Gallery ] |

||||